& gt; Le hoja mokhoa o tšoanang le o kopantsoeng ka lesakana le kopane & gt; Lihlooho tsa BX li ka sebelisoa feela ka 6BX flanges & gt; Litekete tsa BX bakeng sa litekanyo tse phahameng tsa khatello li qala ho lbs 5,000, 'me li fela ka li-20,000 lbs. & gt; Lithapo ha li sebelisoe hape.

BXmofuta oa mefuta e kopanengte bua ka gasket ea tšepe ea karolo e bōpehileng joaloka BX ka ho sebetsa lisebelisoa tsa tšepe. Ke khatello e matlafalitsoeng

ka tataiso ea radial, mofuta o le mong o khethehileng oa tšepe ea tšepe ea octagonal gaskets. E tiisoa hantle ha e le ho kopana pakeng tsa gasket le lenonyeletso

lifahleho, haholo-holo sefahleho sa ka ntle, le e hatelloa ka thata ho boloka mosebetsi o tiisitsoeng hantle.

BXmofuta oa mefuta e kopanengtise kenngoa ka hare ho lesela le kopaneng la sefahleho sa flange. Ha bolt e kopanyang e kenngoa, e hatelloa

kenasehlahisoa direction andispressed close to the upper and lower ring joint grooves, which result kenathe plastic deformation to create the seal.

Ka mor'a khatello is raised, ring gasket expandskenaradial direction under the force of media pressure. The gasket sticks more tightly to the

sefahleho se nang le sefahleho sa moriana ho phomola ho iketsetsa-ho tiisa. Leha ho le joalo, khatello ea khatello ea mecha ea litaba e tla senya flange le ho kopanya bolt, e

tlaetsa hore ho be le karohano e lekanyelitsoeng between the sealingsurfaces, and the sealing ratio ofgaskets is reduced accordingly. BXring type

joint gasketke mofuta o mong oa khatello o matlafalitsoeng ringkets.

Tlhokomeliso: Ha mofuta oa octagonal o khethoa, boima ba thepa e lokela ho ba 15 ~ 20HB tlaase ho feta sefahleho sa flange. Ho joalo

e khothaletsoengho pota ha e sebelisoe hape.

Melao e sebelisoang:

ANSI B16.5-1973, JPI-75-15-70, GB 699, GB1220, JB755, HG20633-97

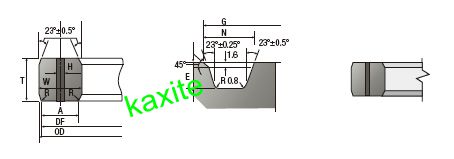

BXRing Joint Gasket Drawings:

Lisebelisoa tse kholo tsa lisebelisoa:

|

Boitsebiso |

Boima bo boholo BRINELL |

Mocheso (℃) |

Lipapiso |

|

|

Brucellosis |

Rockwell |

|||

|

Soft Iron |

90 |

56 |

-60 500 |

D |

|

Steel e tlaase ea k'habone |

120 |

68 |

-40 ~ 540 |

S |

|

304SS |

160 |

83 |

-250 540 |

304 |

|

304LSS |

160 |

83 |

-250 540 |

304L |

|

316SS |

160 |

83 |

-2008 815 |

316 |

|

316LSS |

160 |

83 |

-2008 815 |

316 |

|

321SS |

160 |

83 |

-2008 870 |

321 |

|

347SS |

160 |

83 |

-2008 870 |

347 |

|

410SS |

170 |

86 |

-40 850 |

410 |

|

5Cr-0.5Mo |

130 |

|

-29 650 |

|

|

Koporo |

80 |

|

-100 315 |

|

|

Aluminium |

35 |

|

-2004 425 |

|

|

Inconel 600 |

150 |

|

-100 1095 |

|

|

Incoloy 825 |

150 |

|

-100 1095 |

|

|

Monel 400 |

150 |

|

-100 760 |

|

|

Titanium |

215 |

|

-2005 540 |

|

|

Nickel 200 - |

110 |

|

200 760 |

|

|

Hastelloy B2 |

230 |

|

-100 1095 |

|

|

Hastelloy C276 |

210 |

|

-100 1095 |

|

Ke Hobane'ng ha U Khetha US?

1. Basebetsi

Re fana ka OEM, ODM ea Ring joint gaskets bakeng sa bareki ba rona lefats'eng, e rorisoang haholo ke bareki ba rona

2. Boleng ba boleng bo phahameng.

Re sebetsa ka tieo tsamaiso ea tsamaiso ea ISO bakeng sa ts'ebetso eohle ea tlhahiso le lintho tse tala tse kenang.

3. High Quality Boitsebiso Quarantee

Lihlahisoa tsa rona kaofela ke thepa e phahameng ea boleng ho latela ASTM

4.After tšebeletso

Lihora tse 24 x matsatsi a 7 ka mor'a ts'ebeletso

5. Theko ea Lihlahisoa le Samll MOQ

Re tšepisa theko e tlaase ea fektheri le MOQ e nyenyane.

6Ho Tlisa ka Sekhahla

Bakeng sa mokhoa oa ho etsa mohlala oa ho qeta matsatsi a 3 ~ 7

Bakeng sa nako ea lihlahisoa tsa lihlahisoa tsa nako ea matsatsi a 10-15

Ho laela matsatsi a 7-15 ho ea ka bongata